Destination net zero

How a 50-year collaboration is now supporting the push for clean aviation and driving efficiencies in the air

The global aviation industry is responsible for around 2% of all human-induced CO2 emissions, rising to about 5% of global warming responsibility when adding other gasses and water vapour trails.

This might not seem like a lot, but the UK aviation industry alone is targeting a reduction of just over 30 million tonnes of CO2 per year, to zero. A 50-year collaboration between Rolls-Royce and the University of Oxford is hoping to rise to the challenge by designing more efficient jet engines. Here’s how the partnership is gearing up for sustainable aviation.

Making aviation more environmentally friendly requires today's jet engine designers to meet conflicting requirements.

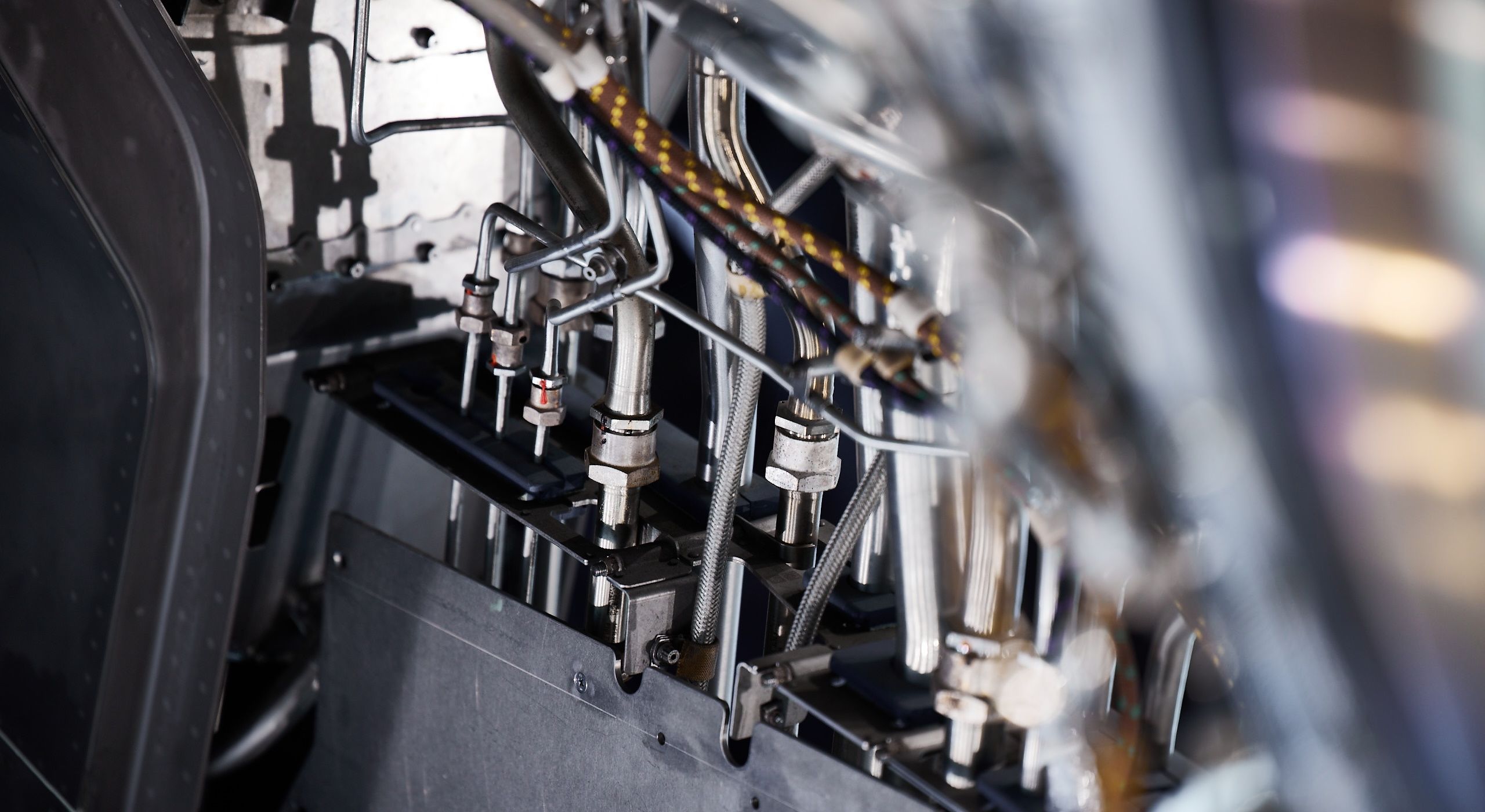

To lower fuel consumption and reduce emissions, engineers must design jet engines that use the air drawn into the engine as effectively as possible to achieve clean combustion at extremely high temperatures. At the same time, the remaining air (not used in combustion) must be utilised to cool parts in the engines that inevitably run hotter than previous generations. The latest jet engines can run with firing temperatures in excess of a staggering 2,000 degrees centigrade.

With air being split between the opposing roles of aiding combustion and cooling the engine, the onus is on engineers to find new ways of using airflow more efficiently.

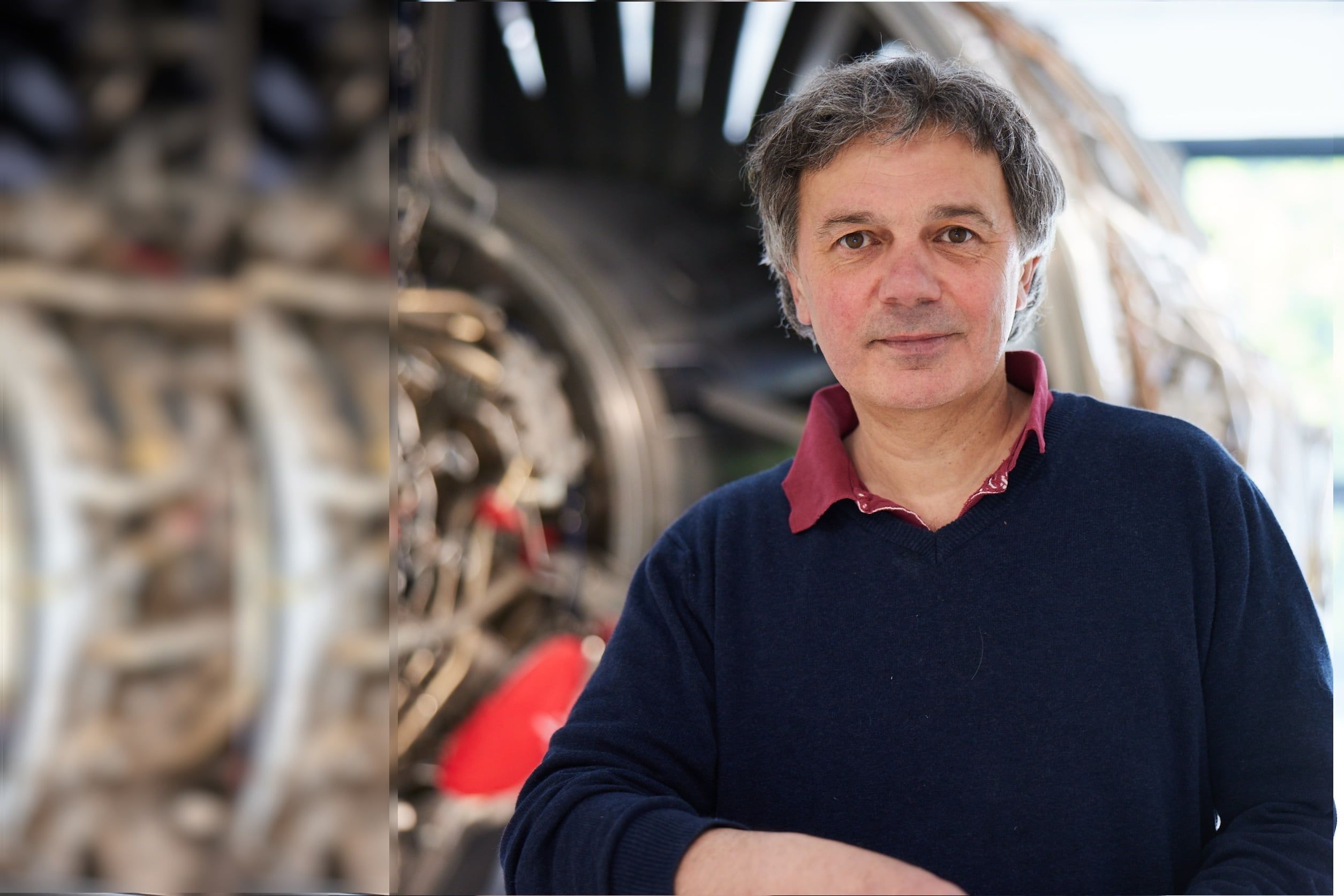

Rolls-Royce has been working with the University of Oxford for the past five decades to access the country's leading experts in the complex field of jet engine heat management. At the Oxford Thermofluids Institute (OTI) a team of engineers, supported by 50 postgraduate students, constantly test the cooling properties of new coatings, materials and airflow geometries so that designs can be incrementally improved.

According to Professor Peter Ireland, Director of the OTI, the team is continually looking for intricate ways of managing airflow to allow engines to run at increasingly high temperatures without shortening their operational life.

The Trent 1000 engine, which hangs from the ceiling at the Institute, is a reminder of how this work leads to real world impact. The engine, which the OTI helped to design with Rolls-Royce, powers the Boeing 787 Dreamliner, which is 20% more efficient than the Boeing 767 it replaced.

'For most jet engines, it's usually a good thing if you can burn fuel at a higher temperature than an earlier generation of engine,' he says.

'You want the engine to run very hot but you want it to have sufficient life, so you cool it by using some of the air that’s going through the engine. You carefully duct or lead it through parts of the engine to protect them from extreme temperatures, and to do that, you have to use complex shapes and forms. The cooling system will have specific geometries, tiny passages, and heat transfer-enhancing configurations.'

Preparing for sustainable aviation

For a truly green future, the aviation industry knows it will need to decarbonise by moving away from fossil-based fuels. In fact, the UK's Sustainable Aviation group, which represents the industry on environmental issues, has become the first in the world to commit its members, including Rolls-Royce, to a pledge of net zero by 2050. To get there will require an international approach, working with governments, customers and suppliers.

It means a radical rethink of aviation fuel. Rolls-Royce sees an important role for hydrogen-powered flight in helping to lower emissions, since the only emissions would be water. However, significant technical and operational challenges remain. The company expects the technology to be used for short haul flights while the storage challenges for powering long haul travel are tackled.

At the same time, Rolls-Royce is working on more advanced technology to develop jet engines that use Sustainable Aviation Fuel, such as biofuels, which are grown as crops, and “e-fuels” produced using clean electricity.

All routes to decarbonising air travel pose novel challenges for jet engine heat management, particularly hydrogen, Professor Ireland explains.

‘There's a lot of interest in using hydrogen because the exhaust gas wouldn’t emit any carbon dioxide, so the OTI is working on engagement in that’

'It presents all sorts of heat transfer problems because you have to drop the temperature massively to keep it as a liquid and then, of course, you have to keep it cool. Eventually, it is going to be burning in an engine, so it's going to be heated up again. That presents all sorts of thermal challenges.'

Five decades of partnerships

Professor Ireland personifies the close relationship between the University of Oxford and Rolls-Royce that has lasted since the 1970s. He studied at the University and became a Professor of Engineering Science before deciding to supplement his academic career with industry experience. After spending four 'great years' working for Rolls-Royce on jet engine development at its manufacturing base in Derby, he was invited back to the University of Oxford to head up the OTI.

This ability to switch between academia and industry is uncommon in the UK compared to some other countries, such as America. Professor Ireland believes it has allowed him to combine focussed industry working with the scientific freedom to explore new ideas in the lab. He says the flexibility to switch seamlessly between the two was helped by the close relationship between the University and Rolls-Royce.

The partnership started when academics at the University demonstrated to Rolls-Royce that they could save time and money by running experiments in University laboratories in short blasts, rather than running engines for extended periods in their factory.

The two institutions have worked together closely ever since. Professor Ireland reveals that the longevity of the partnership, rarely found in academia, is rooted in a mutual respect and understanding that has strengthened over the decades.

'I think it's because we both understand what each other wants,' he says.

‘Rolls-Royce want great science from us, they want great students, they want commitment from the University to fund posts and professorships and to engage in student training. At the University, we like to see our research have an impact and, in this context, our biggest impact has been in reducing fuel burn in jet engines. Going forward, it will be in supporting the push into sustainable aviation.’

This sentiment is echoed by Mark Jefferies, Chief of University Research Liaison at Rolls-Royce. For him, the relationship works so well because the exchange of skills and knowledge delivers huge benefits for both partners, the wider industry and, ultimately, the environment.

'Rolls-Royce has benefited from many decades of collaboration with the University of Oxford,' he says.

'Our partnership began with early research at Oxford that supported the development of the engine used in the Boeing 747 (the world's first Jumbo jet) to our current collaboration on the technologies which will be used for sustainable aviation.

‘Our highly skilled engineers exchange knowledge and expertise with the UK's best academic researchers at Oxford. This partnership addresses our need for world leading solutions to some of the biggest challenges in aerospace engineering – especially those associated with heat flows and high temperatures.'

'This close working relationship has played a significant role in the advancement of our jet engines where engine efficiency is always optimised and environmental impact continually reduced. Oxford has made a fantastic contribution to developing highly skilled young people, ready to take on the technical challenges we face today and will do in the future.'

Close industrial links benefit postgraduates

One of these talented young people, Manuela Sisti, recently won a $10,000 prize from the Zonta International Amelia Earhart Fellowship. Named after the pioneering aviator, the prize is awarded to women breaking barriers in aerospace.

Manuela caught the eye of the judges for the research she is conducting for her doctorate work at the OTI. To manage heat within the highly confined environment of a jet engine, the team needs to be able to measure temperature fluctuation. She is developing an infrared system that can feed live measurements into the computer modelling system, without being intrusive.

'I was put off programmes that were purely science for science’s sake with no input whatsoever to industry or any real-life application because you can spend four years of your life just looking at a tiny problem that won't have any impact on society,' she says.

‘I thought the opportunity to work with Rolls-Royce at Oxford University would be perfect for me because of the cross pollination between academia and industry. I thought, that's going to be really interesting and fun and, at the same time, I will be able to actually see the importance of my research in the real world.’

From working at the OTI with Rolls-Royce, Manuela believes it is giving her the skills and flexibility to pursue a career with a company or in an academic lab, or both. She believes these are benefits that she would not have received had she gone to a university which did not work hand in hand with industry partners.

'Having such a close relationship with an industry partner is great for giving skills to a student so that if they decide not to stay in academia, they have a very enriched CV,' she says.

‘It opens doors and I feel confident that I can go into industry and not be seen as someone who has worked solely in a lab with no understanding of what it means to work in teams with a commercial partner. I'm talking to industry people on a weekly basis, and that's very good preparation for anyone who decides to enter industry after their studies are finished.’

While the Trent 1000 jet engine hanging from the ceiling at the OTI embodies the results of the close relationship, it is postgraduate students, like Manuela Sisti, which bring significant benefits. At any one time, there are fifty students progressing their understanding of jet design in an academic setting whilst also working closely with a world-leading aeronautical business.

This kind of collaboration is essential for the aviation sector to rise to the challenges of sustainable flight and hit its net zero target by 2050.

Inspired by our innovators?

Get in touch with collaboration@admin.ox.ac.uk or visit https://www.ox.ac.uk/research/engage-with-us to see how we could help you make a difference.